A Large number of Robotic Solutions specifically designed for welding automation. The Welding Robot is designed with hollow & solid arms, a number of Axis 6-7 axis, degree of each axis rotation, Speed of each axis, Reach, Payload Capacity, type of Communication, Mobility, Industry 4.0 readiness, etc. A working cell is an independent unit of automation, protected with doors and screens, and built to withstand the spatter & arc light while the process is ongoing. The Robots are customized working cell by setting up for the individual function. Here is an overview for a quick understanding of these features and their utility.

Axis:

A standard 3 axis equipment can turn to 3 directions X-Y-Z. As the number of axis increases, the freedom of movement of the joints also increases. They can not only move towards the basic 3 axes, but also turnaround at specific positions. A 6-axis robot has complete freedom of movement and a seven-axis robot has the extra axis to have better Min & Max reach and move the end tool. Now deciding the right axis for you is simple – does the operation need that amount of flexibility?

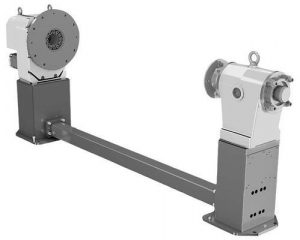

Positioner:

As the name states, a positioner maintains the position of the working piece and rotate it for a specific orientation. They can simply have a single horizontal/vertical axis, rotational on a secondary axis, turntable, H-frame, skyhooks, slider, or linear tracks. The teamwork of the robotic welding arm and a robotic positioner has a huge advantage in welding over the stationary table as it greatly reduces cable damage due to weld spatter in the overhead weld.

MIG/ TIG Welding:

Depending upon the Geometry, Length, and Thickness of the workpiece, you might need more or less features in the work cell. The metal workpiece and the method (metal inert gas, tungsten inert gas, resistance, plasma, laser, ultrasound, etc.) play key roles in determining the equipment you can use. Welding torches have different cooling mechanisms e.g Gas/ water-cooled and shape. The entire working cell has equipment that can match and mount easily to their respective holders.

Spot Welding:

The electrical resistivity of the material has an inverse relation to the levels of current needed for welding that material. A robotic spot-welding work cell can efficiently join metal plates with higher diameters of projection, on metals with low resistivity, endure metal’s thermal conductivity, reduces line currents, accurate current control, quick cycles prevent surround heat and distributes the load. Here the options are two robotic arms or 12 axis robots, a mountable integrated transformer gun or plug, and play gun and laser beams.

Click here . You Know More about welding robotics.