A robotic machine always functions on coordination between its own different components. No matter how standalone the robot may appear, it is still a group of different computerized objects functioning as a whole. With each step of advancement, the machine gets more components, resulting in either better capacity or greater ability. It can get a bit hard to expect one machine to stay on top of all parameters, viz., payload, kinematics, working envelope, speed, accuracy, and degrees of freedom. Each robot is specialized for an industrial purpose. Wherein a classic robot can yawn, pitch, and roll, adding few relevant accessories (aside from the software) to the magazine can make them more versatile and efficient.

Covers: Metal handling workshop is full of dust, coolant humidity, spatter, and cutting debris. The robots working within this environment need extra protection for their cables and joints. The protective gear can range from cable sleeves to special coatings. Each part of the robot has different motions; hence, the accessories can be linear types, box types, conduits, joints, etc. Petty items for higher endurance.

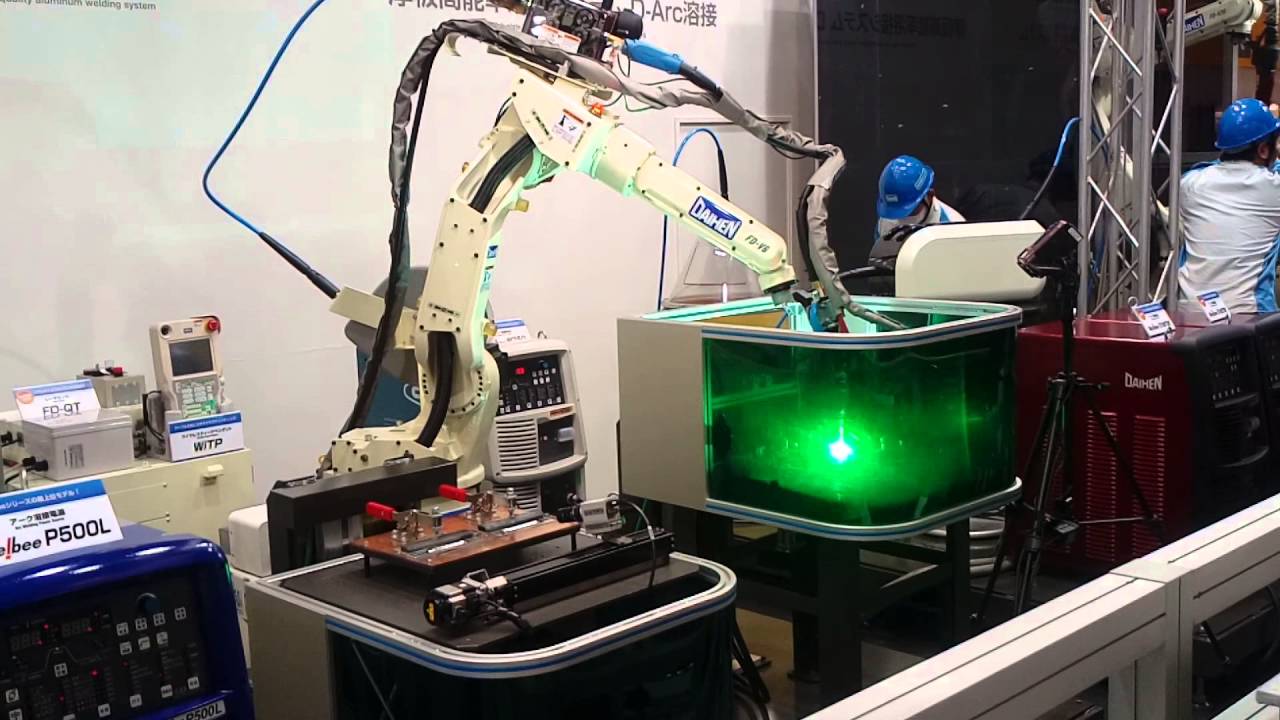

Vision: This is extremely important with a palletizing or a positioning machine. Mainly popularised for smart picking, these integrated cameras are highly useful in no-human zones, and welding is one such zone. The operator can view the working robot on the screen, let it scan the objects in the assembly line, scan the joints, finish, etc. Further to this, the robot can identify the distance between the torch and the object and precisely move the tip to the point for welding. Its 3D sensors can inspect the joint and rework it if needed. Most of the robotic vision cams can be integrated into the modern machine hardware as well as its software. A small tool to smarten up your standard robot.it’s robotics welding.

Cleaning periphery: Wire cutting, brushing, nozzle cleaning, and spatter air blow are essential to maintain the quality in the workpiece and keep the working area clutter-free. Simultaneous cleaning keeps the seam finish visible as well as extend the life of the robotics welding machine components.

Wire Feeder: The inspection and changing of the wire electrode is also an automatic process. In some models, the feeder can be mounted on one of the axes of the bot, whereas in other models the feeder needs to be placed alongside the bot. Several rolls can be placed in one go.

Platforms and sliders: The sliding rails increase the envelope of the bot horizontally. Mobile platforms and lifts serve the same purpose in different directions, dramatically changing the reach of the torch tip.